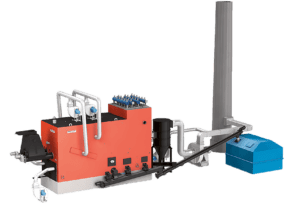

HVTS-G

A turnkey, reliable unit that meets all requirements regarding efficiency, accessabillity and ease of use. Beneficial for both environment and operation economy.

The HVTS-G is a complete unit with grate design that allows the combustion air to be induced in different zones. The brick lined furnace and the ceramic after burner vault make sure that the combustion temperature is at the desired level before the flue gases leave the furnace — this is the key to a clean combustion process. The automatic ash handling consists of an ash scraper that is integrated under the grate cart, and also internal ash and dust augers. These parts helps in keeping the maintenance work at a very low level.

The distribution of combustion air is handled by the primary, the secondary and the tertiary air fan. The fans lead the air into the furnace through holes in the grate and through nozzles in the combustion chamber. The air distribution adapts to the used fuel type and moisture level, a function that helps in achieving optimal combustion.

The flue gas passages are designed so that the dust particles fall down to the bottom of the boiler, from where the they are conveyed outside by the internal augers. Furthermore, the boiler can be equipped with different types of flue gas cleaning and external automatic conveying of ash and dust.